It corresponds to nylon and polyester materials. Processing is possible consistently from scouring of the fabric to shipping of inkjet printed items (direct).

You can also designate the addition of poster processing (water repellent processing etc) after printing of original design and printing.

|

|

|

|

|

|

|

|

1.Quick delivery

Since prepress is unnecessary, short delivery and low cost are realized.

In general, each process of ink jet print preparation, gluing processing and ink jet printing and post processing are often performed in different places, however, Processing is possible consistently from scouring processing to shipment of Inkjet printed products because we have facilities that can handle each process in-house, so that quick delivery is achieved..

“In traditional textile printing, delivery time of about 2 months was necessary, but since plate making and matching are unnecessary, it can be shipped in the shortest two weeks. ”

※ Please submit the image based on the submission condition here.

2.Small batch production

3.High-quality print

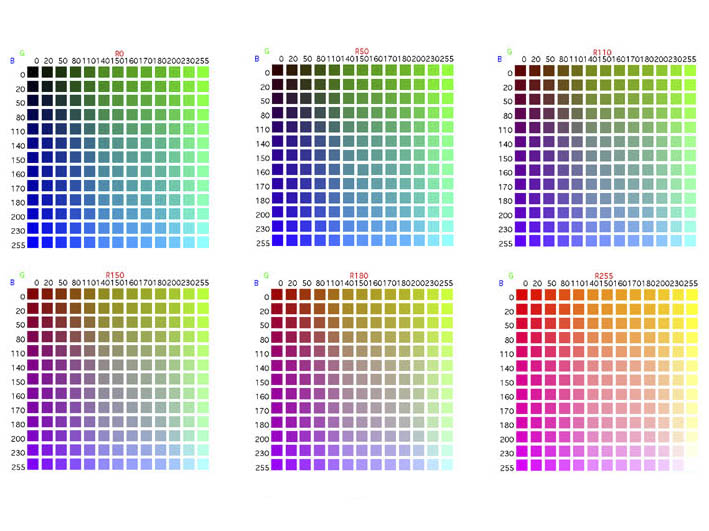

It is 8 colors and 16 heads, we achieved full color printing of 16.7 million colors.

Also, because inkjet printing is possible with a high resolution of 540 × 360 to 540 × 720 dpi, it is possible to reproduce a subtle gradation which was impossible in the version.

4.Supple texture impregnated in the material

5.High dye fastness

6.Easy to change pattern size

Since it is digital print processing, it is easy to print original designs and photographs, enlarge and reduce the pattern size.

In traditional textile printing, another version was necessary due to size change, but it is not necessary for inkjet printing.

7.High-value-added

The history of our inkjet print is about 15 years, but plain dyeing has history over 125 years. It is possible to process additional functions such as water repellent processing and chlorine-free odor processing after printing as well as inkjet printing.

【Difference between traditional textile printing and inkjet printing】

| Comparative item | Conventional printing | Inkjet printing |

| Presence of plate making | 1Version required for each color | No need for prepress |

| Making process | Make-up is necessary for each color, it costs 2 to 30,000 yen per plate, so it will be compatible with large lot. | Significant reduction in cost and time for plate making. Intended for small lot. Mass production is supported in units of 25 m. |

| Resize | Make-up is required again to change the size | Since it is possible to enlarge or reduce the image freely on the PC screen, it is also possible to print a difference in size |

| Maximum print cloth width | 1,600 mm (Actual print width 1,550 mm) |

| Print Speed | Maximum 18 m / h when printed at 1,500 mm width |

| Reproducible color | 16.7 million colors, 256 gradations |

| dye | Disperse dye ink,Acid dye ink |